Functional film products

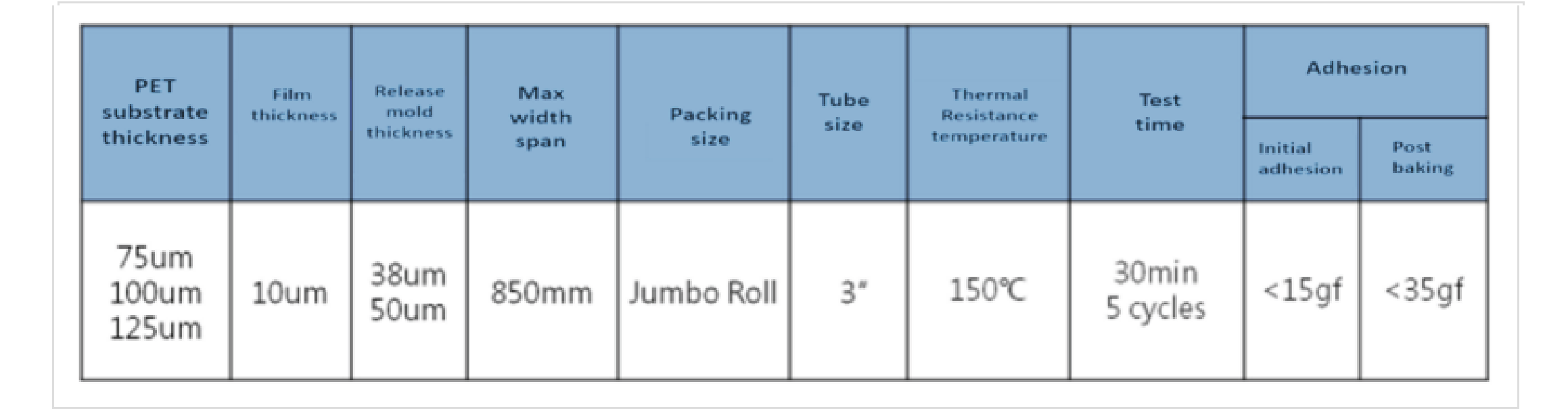

High temperature protective film

- description:

- Thickness, width and packaging methods can be adjusted according to customer requirements

- A variety of specifications of initial adhesive forces and post-baking adhesive forces are available for customers’ choices according to the demands.

- Is of PU plastic category

- No deformation, residual adhesive, white mist, and so forth after the environmental tests.

- Applications:

- Glass touch industry, hot-press attachment protection

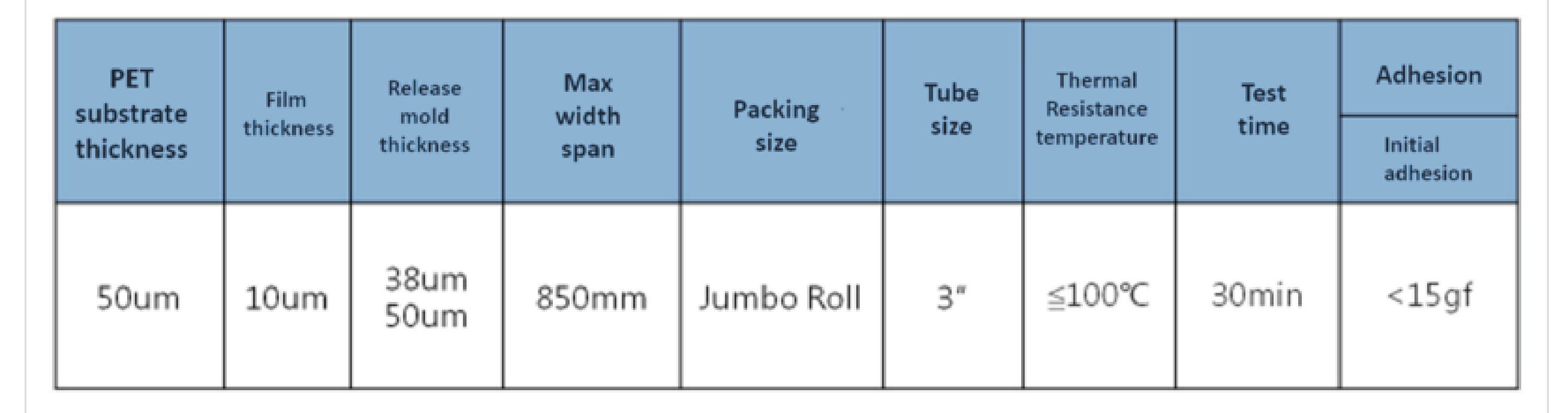

- Descriptions:

- Thickness, width and packaging methods can be adjusted according to customer requirements.

- A variety of specifications of initial adhesive forces are available for customers’ choices according to the demands. If the adhesive forces are not of ordinary specs, that can be handled with additional development projects.

- Is of PU plastic category

- No deformation, residual adhesive, white mist, and so forth after the environmental tests.

- Applications:

- Glass touch industry, protections for in-process or shipping of glass panels

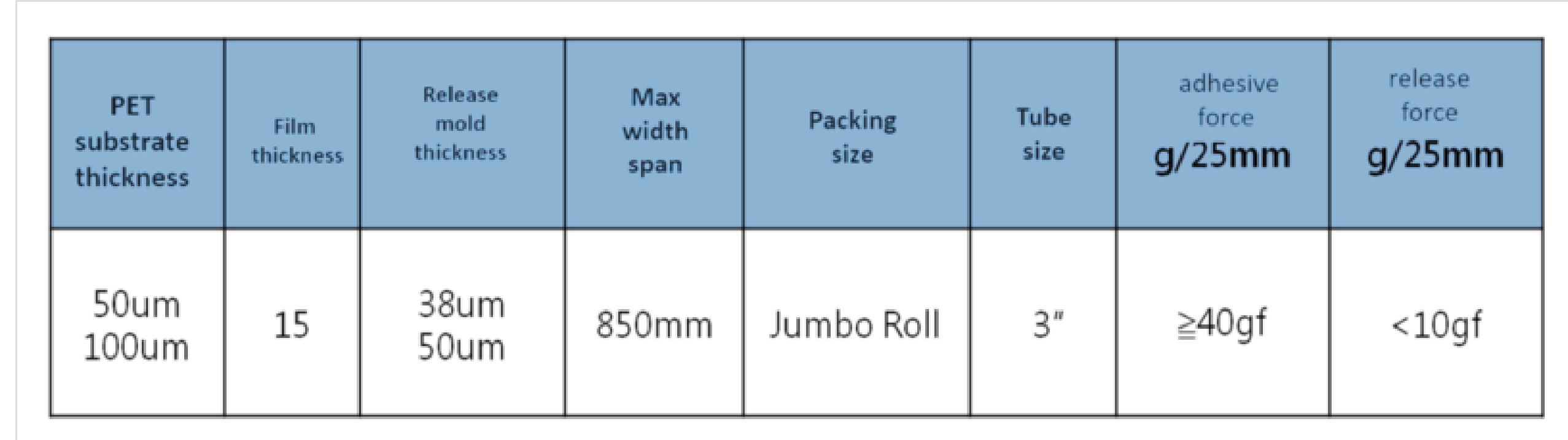

- Descriptions:

- Thickness, width and packaging methods can be adjusted according to customer requirements.

- The adhesive forces can be adjusted according to customers’ production process requirements.

- In the PU acrylic plastic category

- After acid etching, it is not discolored

- Acid etching test conditions, hydrofluoric acid concentration of 25%, temperature 38 ° C, acid-resistant time of 60 min. test substrate, 2mm glass

- Substrates can be converted to PO based materials according to customer requirements

- Applications:

- Glass outer plastic molding, glass thinning, glass secondary/third strengthening, etc.

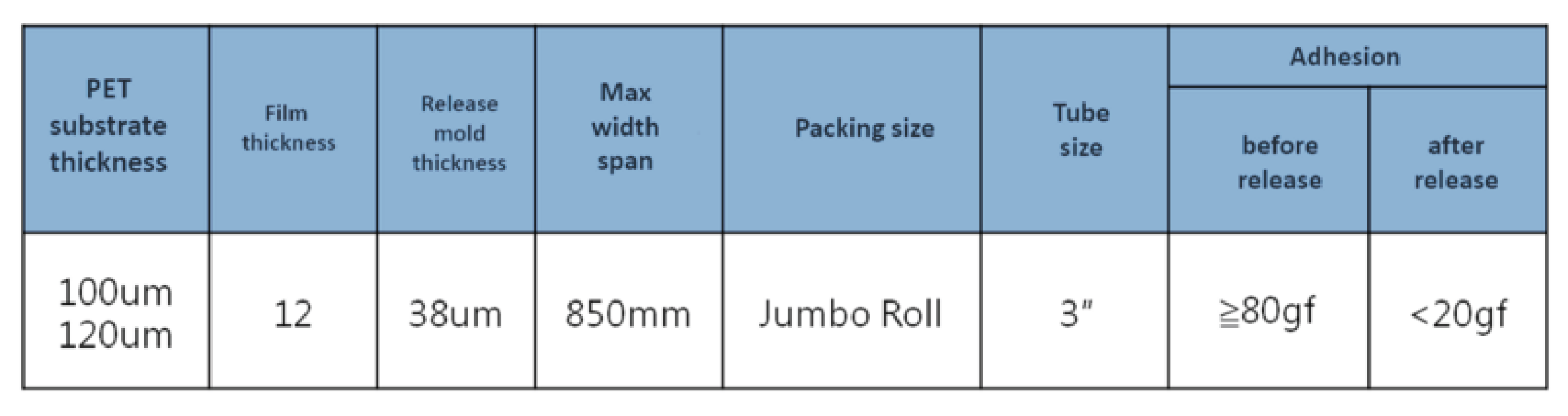

- Descriptions:

- Thickness, width and packaging methods can be adjusted according to customer requirements

- Post UV conditions: >500mj/cm2,test substrate, 2mm glass

- The adhesive forces can be adjusted according to customers’ production process requirements.

- The plastic material is of PU acrylic category

- Applications:

- Protective film in the touch process, protective film for wafer cutting, etc.

- Descriptions:

- Thickness, width and packaging methods can be adjusted according to customer industry requirements

- Thermal release conditions: 150 ℃ 30min, test substrate, SUS steel plate

- The adhesive forces can be adjusted according to customers’ production process requirements.

- The plastic material is of PU acrylic category

- Applications:

- Protective film in the touch process, protective film for wafer cutting, etc.

- High temperature resistant film:

- PU material

- Put a coating onto the PET base film to isolate the PET high temperature powder coating, at the same time proceed with the material pretreatment, and achieve low expansion and contraction product specification requirements

- Suitable for high-temperature ITO film calcining process

- May adjust for different matches according to the customer materials and processes.

- Corresponding products are available for process temperature 150 ℃-200 ℃

- Universal protective film:

- PU material

- 2.Apply an adhesive which meets the requirements onto the PET base film

- Applicable to the use of properties at room temperature

- With features of low viscosity, anti-static, high exhaust and scratch-resistant

- Acid-proof protective film:

- PU material

- Puts a hydrofluoric acid-resistant adhesive onto the PET and PO-based films

- Suitable for glass chemical cutting and glass chemical strengthening process

- Solar release adhesive - Acid-proof protective film:

- PU-Acrylic material

- Apply a light-sensitive, hydrofluoric acid-resistant adhesive to the PET base film

- Suitable for glass chemical cutting and glass chemical strengthening process

- suitable for thin glass

- Thermal release adhesive - acid resistant protective film:

- PU-Acrylic material

- Apply thermal-reaction and hydrofluoric acid-resistant adhesive to the PET base film

- Suitable for glass chemical cutting and glass chemical strengthening process

- Suitable for thin glass

- Suitable for post-enhancement glass which needs ink printing process of thermal baking

- Glass triple strength protective film:

- PU-Acrylic material

- Apply photo-reactive and hydrofluoric acid-resistant adhesive onto the PO-based film

- 3.Suitable for glass chemical cutting and glass chemical strengthening process

- Suitable for post-enhancement glass, need to apply glue for triple strength process.

There are no products to list in this category.